Even the title of this blog adds confusion to a subject that, on the surface, doesn’t seem like it should be that complex. To say there is “proper” installation implies there is also “improper,” in other words just plain wrong. However, some think the assessment of insulation installation quality is in fact much more nuanced than that. Others prefer the more black and white approach. In the face of differences of opinion, where would most in the building industry turn for the final word? To the building code, of course. However, code language may only add to the ambiguity around this subject, and inconsistent code enforcement certainly does. In this blog, we explore the different definitions and terminology related to insulation installation, what code says about it (and what it doesn’t) and why all this matters for home construction, whether it’s code built homes or those meeting more stringent high performance targets.

Terminology and Definitions

There are two primary methods of defining insulation installation quality nationwide: manufacturer’s instructions and RESNET grading. California has its own definition of “Quality Insulation Installation” (QII) which could perhaps be the subject of a future blog.

Manufacturer’s Instructions

Today, fiberglass and mineral wool batt insulation manufacturers provide detailed guidance on how to properly install their products in various building applications. Typically, contracts between builders and insulation installers contain language stating that products should be installed to manufacturer instructions or specifications.

RESNET Grading

RESNET Grading

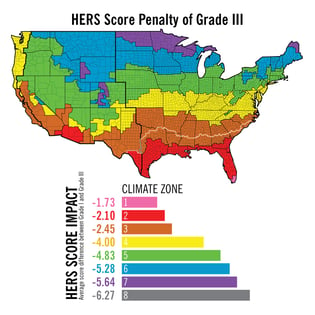

RESNET has its own assessment methodology for insulation installed in HERS rated homes. This methodology is also incorporated into other programs, such as Energy Star and many local incentive and certification programs. This approach assigns installations a Grade I, II or III, with Grade I being the highest and Grade III the lowest. This assessment impacts the HERS score of the home, sometimes significantly (see the HERS Score Penalty of Grade III map, data developed by Ekotrope).

How the Two Differ

Manufacturer’s guidance basically lays out one way, the right way. RESNET’s grading approach recognizes that not all defects are equal; some can have a negligible effect on thermal performance while others can have a significant effect. That makes sense. The problem is that this adds both subjectivity and ambiguity into the process. The small differences in the grading criteria can be difficult to interpret, and grading relies upon visual inspection, meaning results can vary from rater to rater.

Grade I vs. Manufacturer Instructions

This is a critical point. Grade I is the highest score in the RESNET grading system. However, it does make allowances for minor installation defects. Manufacturer installation instructions make no such allowances. In light of this, when we are asked for guidance on the subject we say that insulation, installed to manufacturer’s instructions, would be Grade I. However, a Grade I installation may not fully comply with manufacturer instructions.

Code Language vs. Code Enforcement

For many years, the IECC did not contain insulation installation quality requirements. However, starting in the 2012 IECC, Section R402.4.1.1 of the code states “the components of the building thermal envelope as listed in Table R402.4.1.1 shall be installed in accordance with manufacturer’s instructions”. The table referenced includes insulation, so in other words, the 2012 IECC requires insulation installation per manufacturer instructions. The 2015 and 2018 IECC also have this language. As such, jurisdictions operating on the 2012 IECC or later are in a position to enforce the quality of insulation installation. However, being in a position to do so and actually doing it is not the same thing. Some building code officials may not scrutinize those elements of the code not relating to life safety. For example, building officials may not reject insulation jobs for things like not splitting around wires.

Sorting Through the Ambiguity

A couple weeks back we provided a Guide which presented the business case for builders on the value of insulation installation quality, as well as a list of recommended practices to follow to ensure you get what you’re paying for. We gave a presentation on this guide at RESNET’s annual conference earlier this year. Among the feedback we got was at least one respondent saying “Grade I install is already in a code requirement, so it is not about builder value, they have to do it!” This statement has a degree of truth, but it depends on the version of the code. More critically, trying to tell a builder something is a code requirement, when they know it’s rarely enforced, could fall on deaf ears. That presentation largely precipitated this blog, with HERS raters sometimes saying “I don’t train on Grade I vs. Grade III, I train on proper and improper installation and I cite insulation manufacturer’s instructions.”

Training vs. Inspecting

The comments raised a critical distinction that can help sort through the differences in terminology around this subject: the way you train on proper installation does not have to be exactly how you assess installation quality. One can liken it to the SATs. The SATs seek to assess a student’s verbal and mathematic aptitude, but school is not about teaching you how to do well on the SATs (we hope). It is about giving you the skills and knowledge needed to succeed, including on the SATs. Maybe we can think of insulation installation quality the same way. The RESNET Grading system exists to recognize that, in the field, perfect can be a challenge, so perhaps pass/fail is overly restrictive. Maybe there should be gradations of quality which impact your score. But for manufacturers, insulation contractors, HERS raters and others charged with training people on proper installation it might be best to simplify: train that there is a right way and a wrong way and explain to installers how their work will be assessed in the field. Our guide makes clear that ensuring proper installation is a repeatable outcome comes at the intersection of technical know-how, goal alignment and a set of clear, actionable processes. Getting clarity on how to talk about “proper installation” is a good place to start.

We have lots of resources on proper installation, including:

- Proper installation techniques.These pages are mobile optimized to make them easy to use on a jobsite. In them, we provide location-specific installation images in a simple “do this, not that” format.

- Downloadable pictorial guides in English and Spanish

- A comprehensive video tutorial on proper batt installation

- Short video clips on proper batt installation