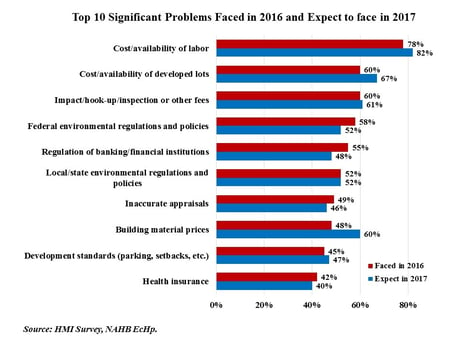

NAHB recently released the results of their monthly Housing Market Index survey which included a set of special questions. The data revealed top builder pain points in 2016, and how builders expect these pain points to change in 2017. The top problem continues to be cost and availability of labor, which builders see increasing in 2017. Interestingly, the problem which showed the greatest increase 2017 vs. 2016 is building material prices, which jumped 12 points (the next biggest change was 7 points). HERS Raters, in their consultative function for builders, can play a role in addressing this key pain point relating to insulation costs. Here are three specific ways raters can address builder cost concerns:

NAHB recently released the results of their monthly Housing Market Index survey which included a set of special questions. The data revealed top builder pain points in 2016, and how builders expect these pain points to change in 2017. The top problem continues to be cost and availability of labor, which builders see increasing in 2017. Interestingly, the problem which showed the greatest increase 2017 vs. 2016 is building material prices, which jumped 12 points (the next biggest change was 7 points). HERS Raters, in their consultative function for builders, can play a role in addressing this key pain point relating to insulation costs. Here are three specific ways raters can address builder cost concerns:

1. Demonstrate Cost Savings

Last year NAIMA commissioned research into builder opinions of HERS raters (and vice versa) and rater opinions of subs and insulation installation quality. The results showed that builders who frequently work with raters “feel” raters deliver value, but they struggled at times to articulate exactly what this was (besides the obvious of providing a rating, a certification, rebate approval etc.). Builders all had stories of raters who helped improve their homes through their knowledge of building science, new products and practices and training subs--services that provided a value that they “felt” but didn’t necessarily “see.” Builders were most excited by examples of rater actions that provided direct cost savings. Raters would do well to lead with their stories of direct actions and recommendations that led to builder cost savings.

2. Cost Optimize HERS Scores and Insulation

The HERS system for insulation is straightforward: you get points for certain R-value levels. These points are reduced when installation quality is lower. For Grade III, the reduction is essentially 5%. In other words, 5% of the R-value a builder pays for is wasted in a Grade III installation. This basic fact is true regardless of the insulation used. Put another way, insulation type is irrelevant in the HERS system except with regard to installation quality (leaving continuous insulation out of the equation, for the purpose of this discussion). Builders who want to maximize HERS scores and minimize costs must use the most cost effective insulation available and have it installed properly, i.e. to Grade I. The insulation option most capable of delivering this is fiberglass batts. Yes, there can be incremental costs for installer labor (addressed in a previous blog). There could even be incremental costs for rater labor to set quality expectations, educate installers and ensure work is up to snuff before the actual grading assessment occurs (we talked about this, too, in a number of previous blogs). But the real question is how total costs, meaning incremental labor for the rater and installer plus typical labor/material costs, compare to other insulation solutions.

3. Be a Rater Who Fills Both Sides of the Ledger

Not all value can easily be assigned a dollar figure. People are often paid for expertise even if that expertise cannot readily be translated into incremental dollars saved, or earned. But, if you are a rater who knows that builders wants cost savings, understands that material prices are a rapidly growing pain point and wants to be a real consultant to your builder customer, you ought to be on the lookout for ways to address all three of these wants. A rater who uses smart processes to deliver Grade I with batts, and saves builders money by doing this vs. using other insulation products, can ensure builders both “see” their value in dollars saved as well as “feel” it in many other ways.