Custom home buyers have very discriminating requirements when it comes to designing and constructing their homes. Increasingly, those needs incorporate the desire to be sustainable and energy efficient. When sustainable architectural firm SUSTAINABLE.TO Architecture + Building and Greenbillt Homes, a leading Canadian custom home builder teamed up design and construct a home in North York, Ontario, they were directed to deliver a tall order to their clients: designing a home that would “sip energy, endure for generations and remain comfortable at all times.” The result was a striking residence that incorporates mineral wool insulation and delivers some impressive energy performance results.

Custom home buyers have very discriminating requirements when it comes to designing and constructing their homes. Increasingly, those needs incorporate the desire to be sustainable and energy efficient. When sustainable architectural firm SUSTAINABLE.TO Architecture + Building and Greenbillt Homes, a leading Canadian custom home builder teamed up design and construct a home in North York, Ontario, they were directed to deliver a tall order to their clients: designing a home that would “sip energy, endure for generations and remain comfortable at all times.” The result was a striking residence that incorporates mineral wool insulation and delivers some impressive energy performance results.

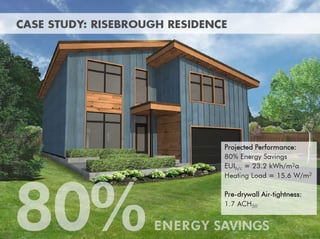

Risebrough Residence

The home, known as the Risebrough Residence, required innovative design and high-performance building materials to achieve its air tight, high-efficiency goals, along with careful collaboration between the architect and the builder.

The team wanted to address the issues of condensation control, thermal bridging, air tightness and energy efficiency, all while using conventional, yet more sustainable and environmentally-conscious building materials. For project the architect and builder adapted a wall system method they had previously tested known as the Toronto Method Wall Assembly.

The code minimum wall assembly in Southern Ontario’s extreme climate (where temperatures can reach 90° Fahrenheit in the summer and -31° Fahrenheit in the winter) only considers that vapor drive is from the inside out. That’s fine in the winter, but in the summer, the vapor drive is the other way around, so the polyethylene sheeting (vapor barrier) is in the wrong place, allowing it to trap moisture as the vapor cools and condenses on the poly sheet.

The Toronto Method Wall

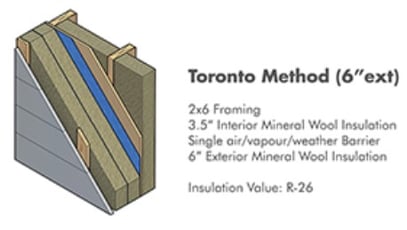

The Toronto method recognizes that you can achieve a better building envelope by using the right materials in the right place. It also embraces the easiest and lowest cost passive house measures, which is to first reduce the overall energy demand on the home. The team started with two-by-six framing which was then filled with 3.5 inches of mineral wool insulation.

Mineral wool was used both inside and outside the home because of its high recycled content, natural content, high R-value, moisture repellant capacity, fire resistance and because it could be locally sourced. Mineral wool insulation used in residential construction in becoming increasingly popular for the reasons mentioned previously as well as its resistance to mold and mildew.

Framing 2 X 6 studs allowed plumbing and electrical to be installed inboard of the insulation, resulting in a better fit and reducing heat loss through thermal bridging. Outboard of the sheathing, the Toronto Method calls for a single, continuous rigid mineral wool board insulation installed around the home’s exterior, preventing thermal bridging almost completely. Two three-inch layers of the rigid board mineral wool were used for a total thickness of six inches. With a balance of two-thirds of the insulation on the outside of the home, and 1/3 on the inside, placement of the vapor retarder becomes unnecessary. Instead, the plywood sheathing acts as a vapor retarder, slowing transmission of vapor and allowing the wall system to dry to the inside and the outside per seasonal vapor drive in Toronto’s extreme climate. With a tight, but breathable building envelope, the home’s energy demands are significantly reduced. The wall system is finished with wood strapping and lightweight cladding.

Conclusion

A blower door test of the completed structure to resulted in a reading of 1.7 ACH50 — which is a 35 reduction in energy use from air-tightness alone. Overall, the Risebrough Residence achieves an 80 percent more efficient than a conventionally built home. The Toronto Method Wall Assembly was one of the strategies used to reach greater energy efficiency, but the home also incorporates passive house and other energy efficiency measures, delivering on the customer’s initial requirements and surpassing performance expectations.

The durability of mineral wool insulation makes it an attractive option for U.S. builders. It’s common in multi-family structures and increasingly common in single-family home building.

Builders, architects and others who want to learn more about the advantage of using mineral wool in residential and commercial can complete a new course, offered by Hanley Wood and NAIMA. The course also offers 3 CEU credits for architects